Innovative tooling for the manufacture of aircraft componentry.

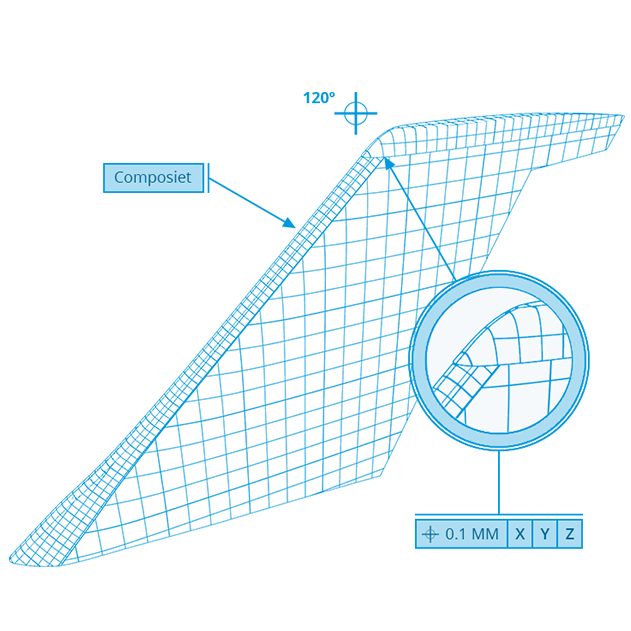

The current manufacturing process of a stabilizer component must be divided into sub-processes and go from serial to parallel production. Our mission is to replace the existing tail piece with a number of high-tech sub-assemblies.

By using secondary jigs, we improve the manufacturing process and save time.

The result is a method by which production is not only improved, but its rates can also be increased.

Our aerospace engineers take all our clients’ needs into account.

The needs of our customers come first. For example, this finished assembly measures 3 by 6 meters and requires a positional accuracy of +/- 0.1 mm.

It is not a problem for our experienced aerospace engineers. They can not only guarantee stability, accuracy and ergonomics, but ease of use, durability and adjustability by the use of lasers and coordinate measuring machines.

Aerospace engineering at its best.

From concept to 3D engineering; the realization of the 2D drawing package to manufacturing and installation. Complete turnkey solutions.

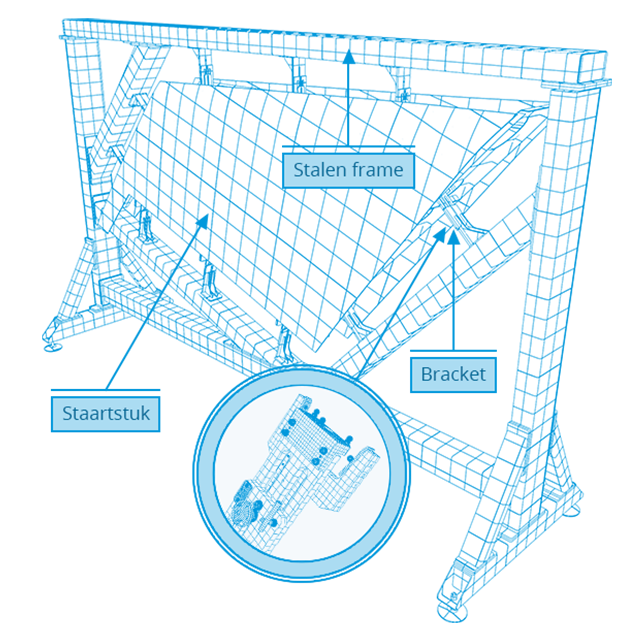

The jig being manufactured consists of a steel frame fitted with high tech clamps.

All the individual parts of the tail section are clamped together in exactly the right position. This includes ribs, frames, hinges and the outer-skin. All these components will all be secured accurately together inside the jig.

During the draft process, our lead engineers turn fledgling ideas into usable concepts.

Our lead engineers and the client decide on the best solutions and combine them into one concept. This concept is then formed into a complete 3D model in CAD software such as Catia V5. Once 3D models are completed, they are used as a basis to compose a 2D drawing package. These drawings are used by Famag for manufacturing.

After the jig has been delivered, it will be assembled on site and adjusted, using a laser tracker. This allows the positioning of the components to a precision of +/- 0.05 mm.

Perfection and quality; that is what we do, nothing else.

Our clients

Building the future together with the companies of the future.

How can we help you?

Please contact one of our specialists

Working at Amstel Engineering

Will you push engineering to the next level?